Camera and laser technology’s relentless progress can be used in numerous domains, from medicine to entertainment, and security to food processing. Potato product manufacturers, too, are reaping the benefits. At Optimum Sorting, a high-tech sorting systems developer, innovations follow in quick succession.

© Optimum Sorting

© Optimum Sorting

“With our VENTUS, we can now even detect wet rot in potatoes, while our NOVUS does the same with tiny metal particles in French fries,” says Alexander Dewilde, the company’s agent for Belgium and France. It is now also easier and faster to scan a French fry’s sixth side.

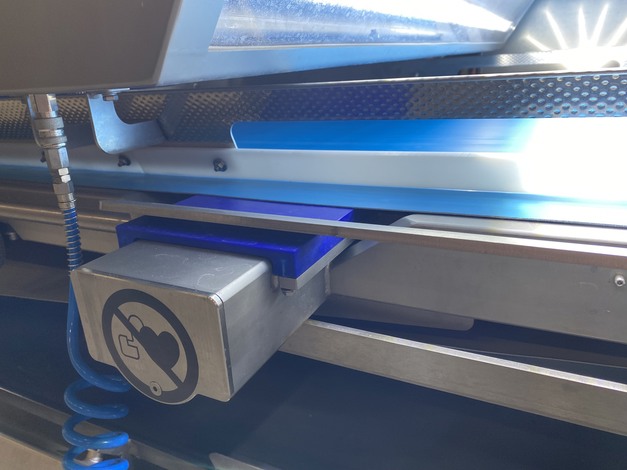

Worldwide, there are already 800+ Optimum machines in operation, and that number keeps rising. The NOVUS belt sorter for potato products, nuts, and vegetables is one of the company’s flagship products. “Depending on the application, we install three, six, or nine high-resolution cameras as standard. These detect color deviations, unusual shapes, and sizes with great accuracy. To single out foreign material, the machine is equipped with a laser box with a 0.3mm resolution, the highest on the market.”

© Optimum Sorting

© Optimum Sorting

Line has ultra-fine metal detection integration

A new feature of the NOVUS is the addition of the M-TEC: an advanced metal detection module. It is integrated into the frame and can be added at any time, even after installation. It is a vital feature since metal particles are not always visible to cameras or lasers. Many French fry factories already use metal detectors at the check weigher when the bags are filled. This extra, early-stage control, however, offers crucial advantages.

Low-maintenance optical imaging of fry’s sixth side

During optical sorting, a device closely inspected French fries on five sides. The sixth side—the one resting on the conveyor belt—though, presents challenges. “We now have a solution. We carefully scan that last side, from beneath, when the fries leave the belt. That’s nothing new, you might think. But many systems’ lower cameras struggle with contamination. They get starch on them, which can lead to false positives or no image at all. Then you have to clean those cameras,” says Alexander.

© Optimum Sorting

© Optimum Sorting

Optimum Sorting found its answer in the maritime shipping sector: a spinning window. “The camera looks through a rapidly rotating glass. Any dirt is immediately thrown off, so you always have a clear view,” Alexander explains. “A French customer is already using this and is very satisfied.”

Finally, you can see wet rot

The most significant innovation is perhaps wet rot detection in potatoes. “That was always a difficult issue. A batch of potatoes can be rejected because too much wet rot is found in the sample. That happens more often in wet years.” Also, once the potatoes have been washed, wet rot is almost impossible to distinguish visually from the skin. “Cameras can’t see the difference. Our new laser configuration can,” Alexander concludes.

© Optimum Sorting

© Optimum Sorting

Optimum Sorting has a demo center in Hasselt, Belgium, where interested parties can get a demonstration, free of charge, with their product.

Alexander Dewilde|

[email protected]

Optimum Sorting

Zolderse Kiezel 36

3511 Hasselt (Kuringen)

E: [email protected]

W: www.optimum-sorting.com